The skills shortage is compounded by the fact that training people to use CNC machines, and similar tools, is expensive, slow and potentially dangerous. Training Uses Accurate and Interactive Physical Simulator In the US, for example, job openings are hovering near all-time highs at 800,000 with 55% of roles unfilled (Deloitte 2023 Manufacturing Outlook), while almost three in 10 manufacturing firms in Europe reported production constraints in the second quarter of 2022 due to a lack of workers (World Economic Forum, Future of Jobs Report, 2023). HxGN Machine Trainer was developed by Hexagon to help companies and educational institutions attract and train the next generation of machine workers – something that is vitally important with the industry facing a skills and labour shortage.

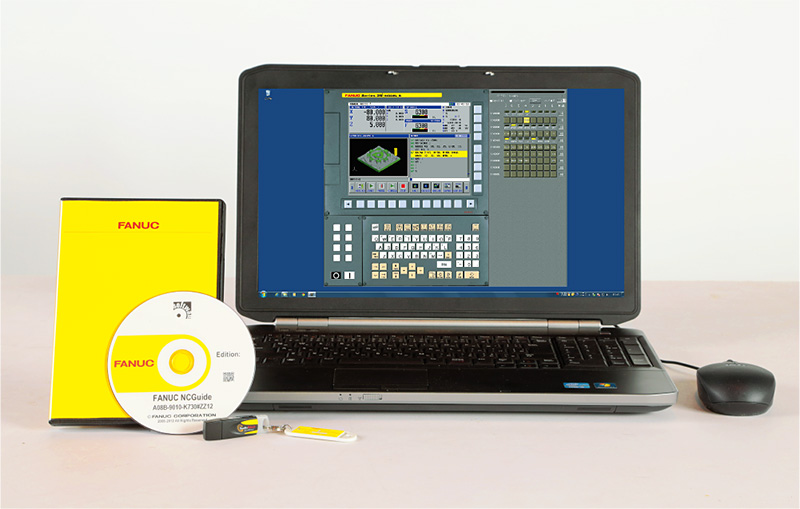

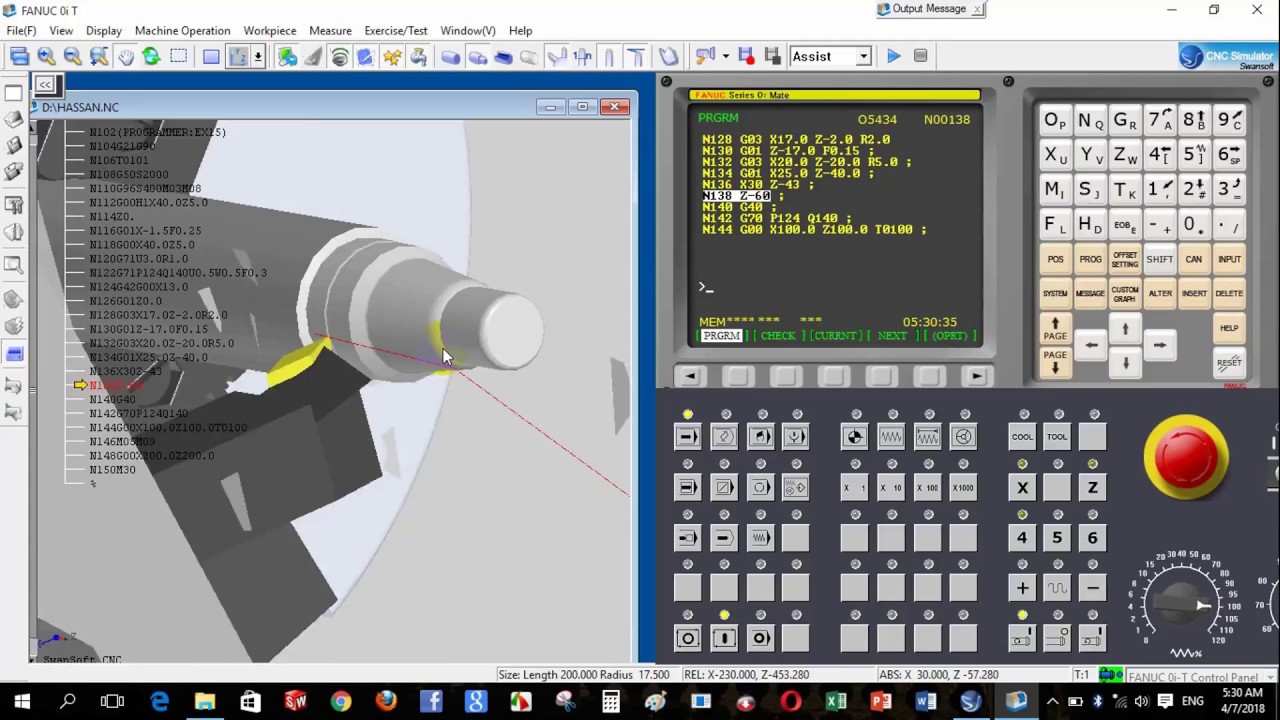

By combining hardware that realistically replicates machines with manufacturing simulation and operator’s software tools, it helps trainees gain practical experience without risking damage to expensive business-critical equipment, wasting materials, or tying up valuable production resources.

New training technology available globally from Hexagon’s Manufacturing Intelligence division leverages the power of its digital twins to help manufacturers train machinists and metrology specialists to use valuable shop-floor equipment.

0 kommentar(er)

0 kommentar(er)